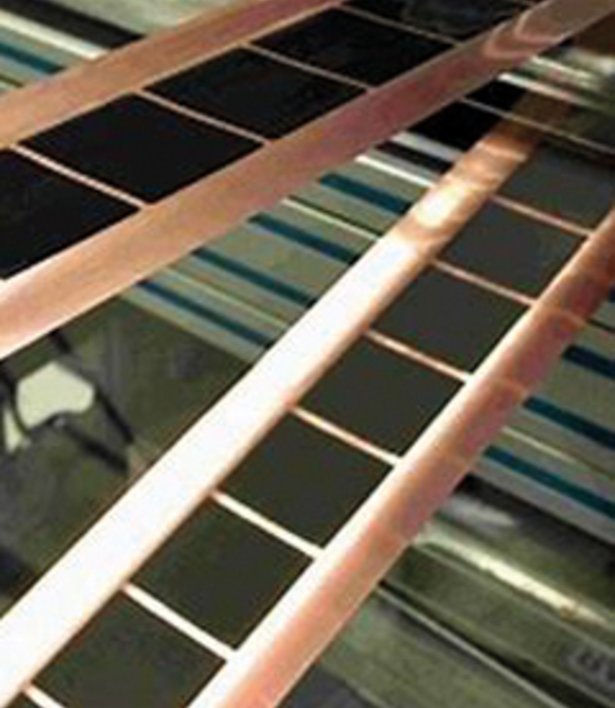

Innovative research combined with specialized mechanical engineering

The benefit COATEMA offers its customers lies in the combination of innovative research, an integrated R&D centre and specialized mechanical engineering. The close interlocking of these three elements enables rapid processing and familiarization with new technologies and markets. In today’s technology markets such as renewable energies, printed electronics and sustainable packaging, COATEMA customers need integrated, innovative solutions.